PROCESS

HAIJUN Co., LTD., a leading Specialized Seaweed Company for Export

Manufacturing Procedure

Take a look at our entire procedure from harvesting raw seaweed to manufacturing.

Harvesting Raw Seaweed

Natural seaweed spores are grown from November to May in the uncontaminated sea during Winter and harvested in the best condition. (*Approximately 14-15cm in length, 5-12cm in width)

Auctioning Raw Seaweed

On the day that the raw seaweed is harvested, we go to the site to meticulously check the quality by seeing and feeling the raw seaweed firsthand and pick out the best raw seaweed.

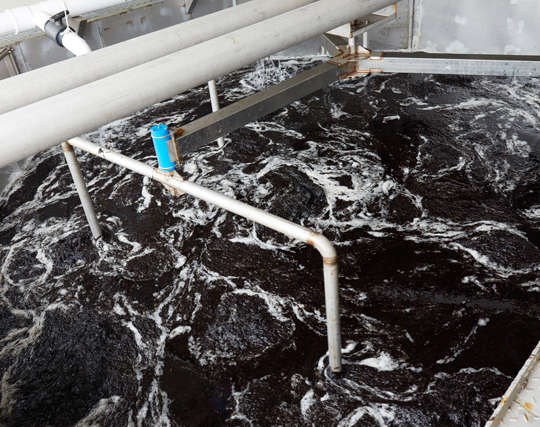

Storing and Washing

We quickly move the fresh raw seaweed harvested from the sea to our large stainless water tank and store it to eliminate the possibility of contamination and to retain the nutrients and quality.

Initial Process

Through the designed state-of-the-art automatic system, we safely wash the seaweed with 100% tap water for removing foreign substances, washing, dehydrating, and ripening. (*Our tap water is the safest water that is strictly managed under the Water Supply and Waterworks Installation Act)

Shaping and Drying

We shape the seaweed evenly in the most adequate thickness for consumers’ requests and slowly dry it. (About 9% water content)

Checking and Packing

We meticulously check the end product for metal and foreign substance residue, and then carefully pack the product.

Shipping and Storing

We ship or store the end product.